Home | Strip Lamination Ultrasonic Inspection Systems

Home | Strip Lamination Ultrasonic Inspection Systems

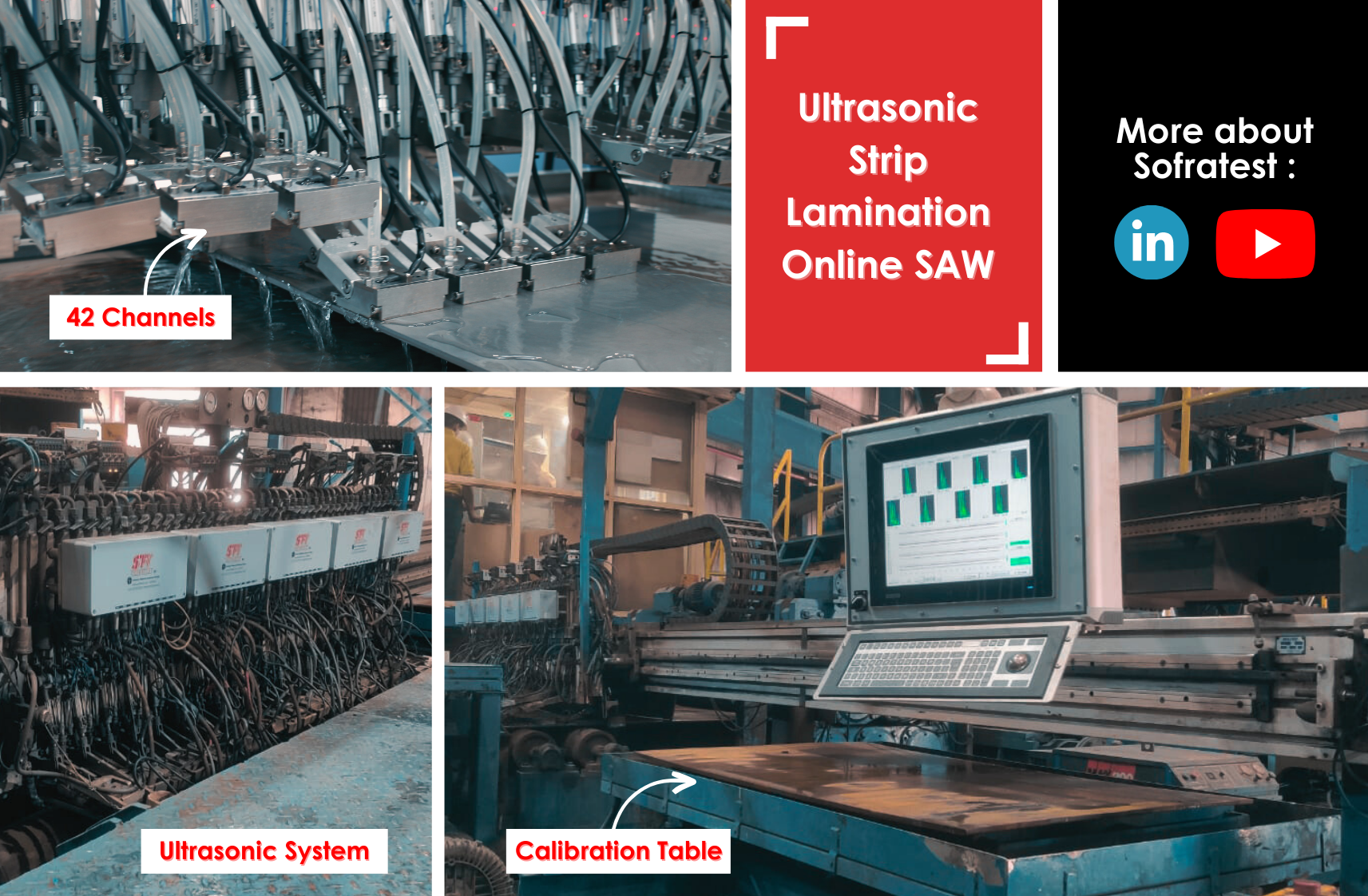

We are thrilled to announce the successful revamping of our Ultrasonic strip lamination inspection system at a customer site in Saudi Arabia.

For enhanced inspection quality and improved performance, the system’s electronics have undergone a complete overhaul.

This ensures a more modern Ultrasonic system, continuous maintenance and optimal functionality. ✔

Featuring 42 channels, this system enables comprehensive inspection of the entire strip, including its edges, before the formation of SAW pipes. Positioned at the initial stage of the online station, it efficently identifies any lamination defects.

The number of Ultrasonic transducers is determined based on the width of the strip under inspection. Adjacent to the system, a calibration table ensures dynamic calibration, allowing constant verification of settings during inspections to guarantee high-quality results.

All inspection outcomes are prompty displayed, processed, and analyzed in real-time using our software. These results are meticulously compiled to generate a comprehensive inspection report.

The Sofratest system is fully adaptable to customers’ needs and adheres to European and international standards, such as EN 10893-9, EN 10160, SEL 072, ASTM A578, ASTM 435M, BS 5996, API 5L 46th, ARAMCO and more. ✅

All our systems are individually crafted in our in-house French workshop, empowering Sofratest to deliver turnkey solutions precisely tailored to our customers requirements.

Do you have NDT projects ? Reach out to us ! We offer specific solutions tailored to your needs.

📧 : sales@sofratest.com

📞 : (+33) 01 34 75 50 00

#ultrasonic #saw #pipes #tubes #inspection #defects #detection #strip

Contact Details

6 rue des Loches

71100 SEVREY | France

Phone : +33.1.34.75.50.00

E-mail : sales@sofratest.com