Home | Electrical Resistance Welding (ERW) | Scarfing Monitoring Process (I/O Profile)

Home | Electrical Resistance Welding (ERW) | Scarfing Monitoring Process (I/O Profile)

SOFRATEST offers Ultrasonic solutions for I/O profile and wall thickness analysis in ERW pipes.

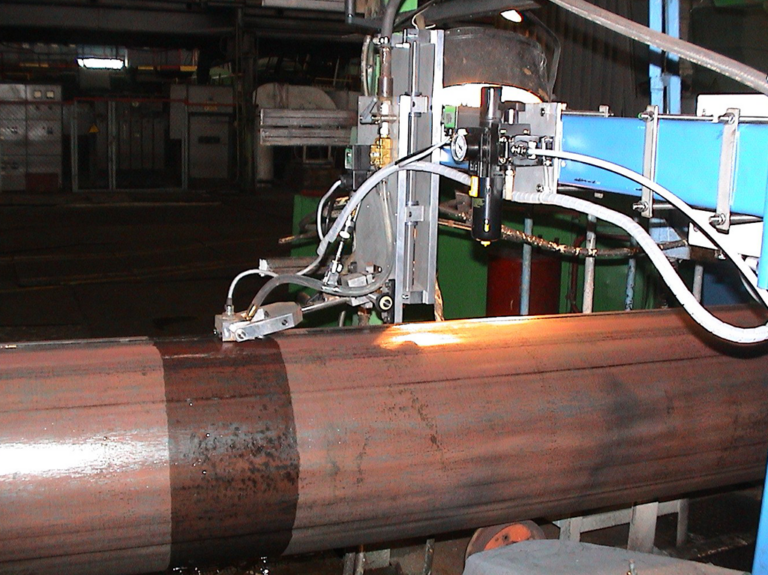

The Scarfing Monitoring System is strategically placed immediately after the welding process.

A security sensor can be added to the system as an option ensuring greater safety and serenity before the use of the IOP system. It will detect potential open welds, in order to ensure the execution of the Scarfing Monitoring System without any damage.

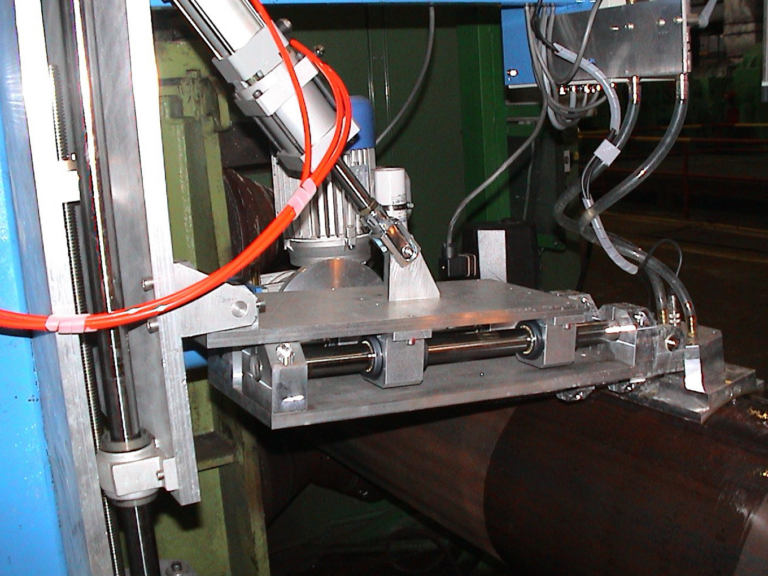

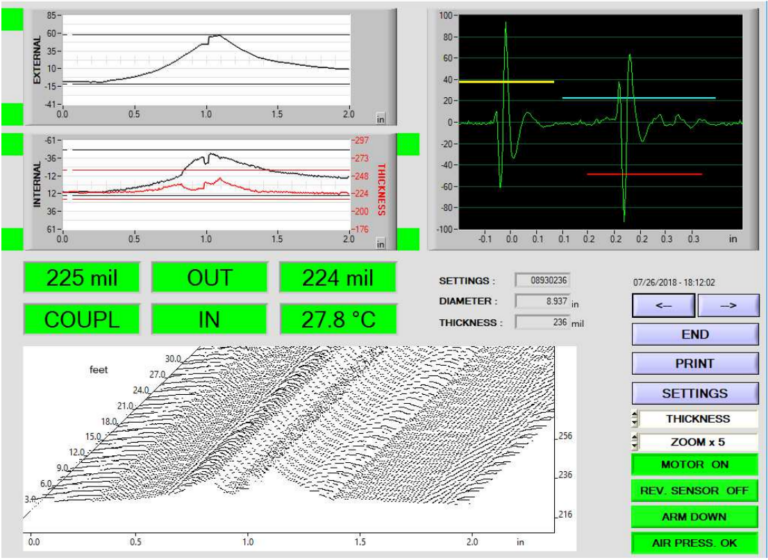

Following the security sensor, a probe shoe oscillates around the weld, inspecting both the external and internal profiles of the weld, while simultaneously performing a thickness measurement.

This equipment offers high stability, allowing for high-speed inspection under very harsh conditions.

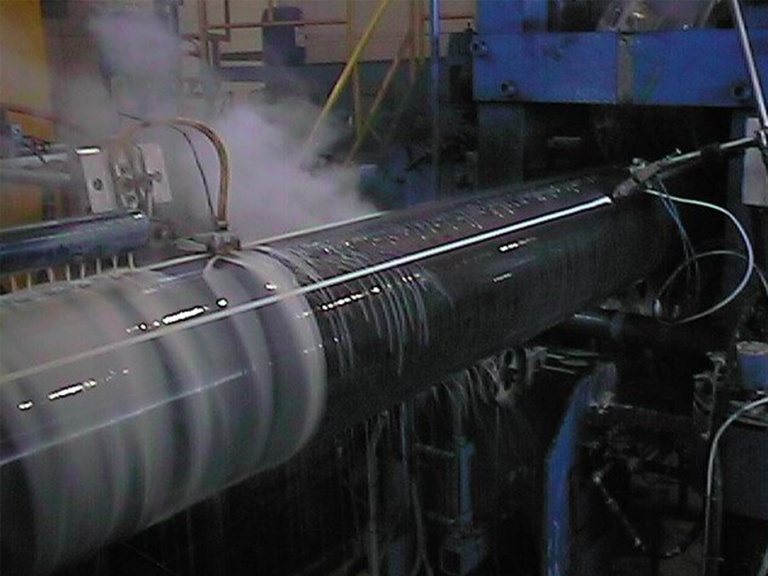

Prior to inspection, the weld undergoes cooling with a cooling liquid (utilized as a coupling agent).

Our equipment can be adapted according to the diameter, thickness, and length, of the pipe, enabling a comprehensive 100% inspection of the product.

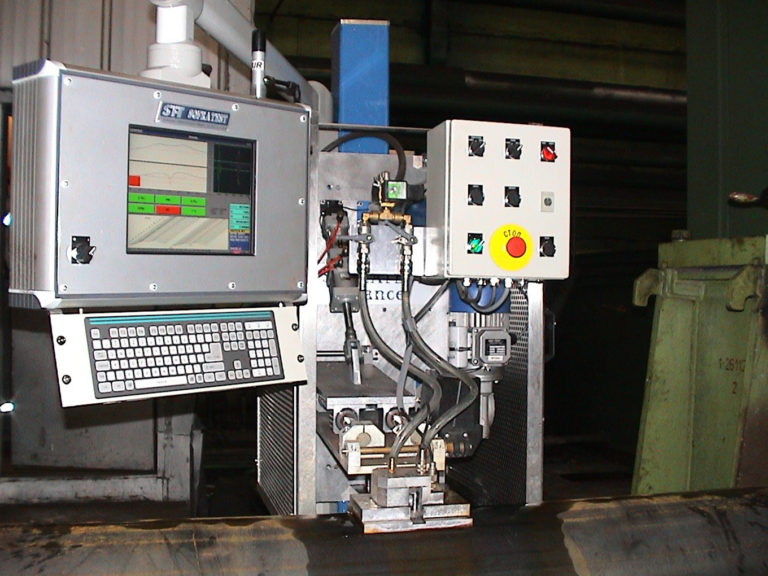

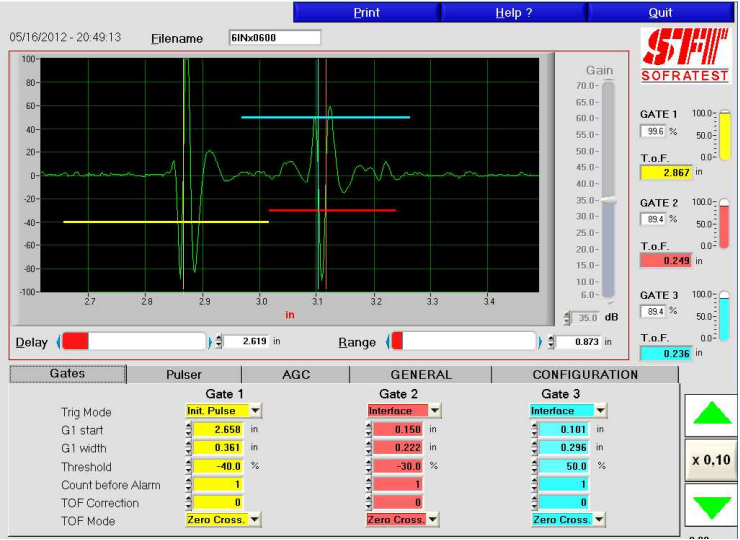

The powerful and user-friendly IOP Software enables real-time display of successive profile curves along the pipe. This includes the external profile, internal profile, thickness profile, or a simultaneous display of both external and internal profiles.

The system screen is accessible remotely, providing a clear, comprehensive view of the ongoing inspection and allowing necessary adjustments to be made in real-time.

All our Ultrasonic systems comply with European and international standards, including ASME Section V, ISO 10893-11, 10893-8, 10893-10, API 5L, API 5CT, ASTM E317, and more.

High Inspection Speed

Equipment Resistant to Harsh Conditions

100% Adaptable Systems

Easy to Use Software

Real Time Results Display

Contact Details

6 rue des Loches

71100 SEVREY | France

Phone : +33.1.34.75.50.00

E-mail : sales@sofratest.com