Home | Ultrasonic Lamination Inspection of SAW Strips

Home | Ultrasonic Lamination Inspection of SAW Strips

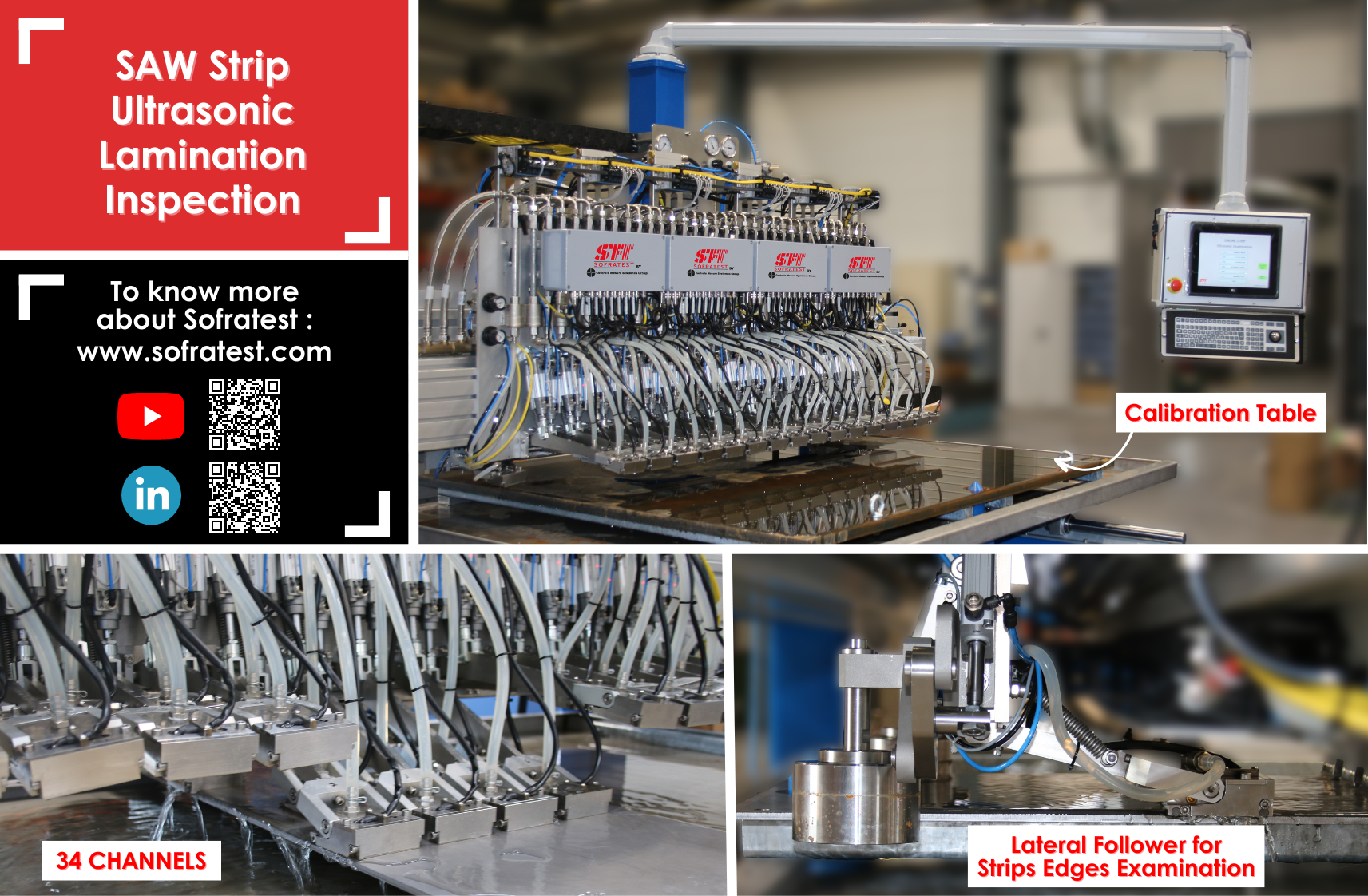

SOFRATEST has designed and manufactured all the electrical and mechanical components for a complete Ultrasonic online strip lamination inspection system for SAW pipes.

This system has the cability to perform a full inspection of the strip before it is rolled into a pipe:

👉 For the strip body inspection: 32 dual element probes are used

👉 For the strip edges inspection: 2 dual element probes are used

The system allows the inspection of strip width from 400 to 1,600 mm and thickness from 5 to 30 mm: adapting to the entire width of the strip to be controlled!

The entire system moves laterally on a calibration table allowing a dynamic calibration at the same speed as the mill. This position is also used as a safety position during the change of coil. Calibration is performed as soon as necessary at regular intervals and a complete report is generated for each calibration.

This entire application complies with the following standards: API 5L, 46th edition-2018. ✔

The electronical part of this application is composed of a PC UT and a PC process enabling the display of inspection results in real-time and the creation of a complete report after the control.

👉 Contact us for more information: sales@sofratest.com

Contact Details

6 rue des Loches

71100 SEVREY | France

Phone : +33.1.34.75.50.00

E-mail : sales@sofratest.com