Home | Strips lamination inspection

Home | Strips lamination inspection

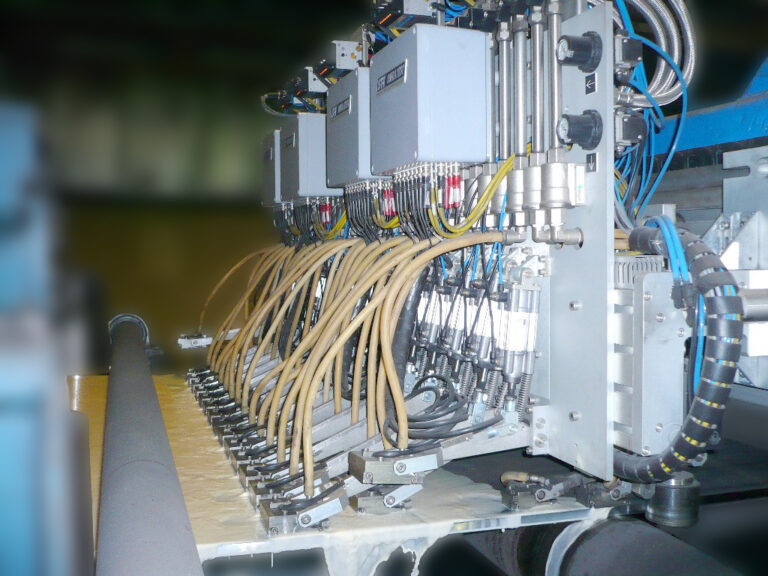

Thanks to our Ultrasonic expertise, we design and manufacture in-house our UT tailored transducers to suit your detection needs according to your product range.

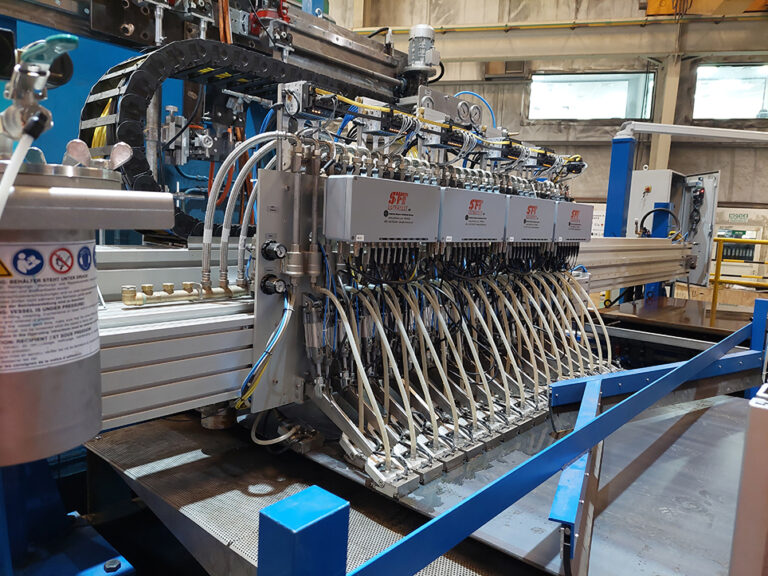

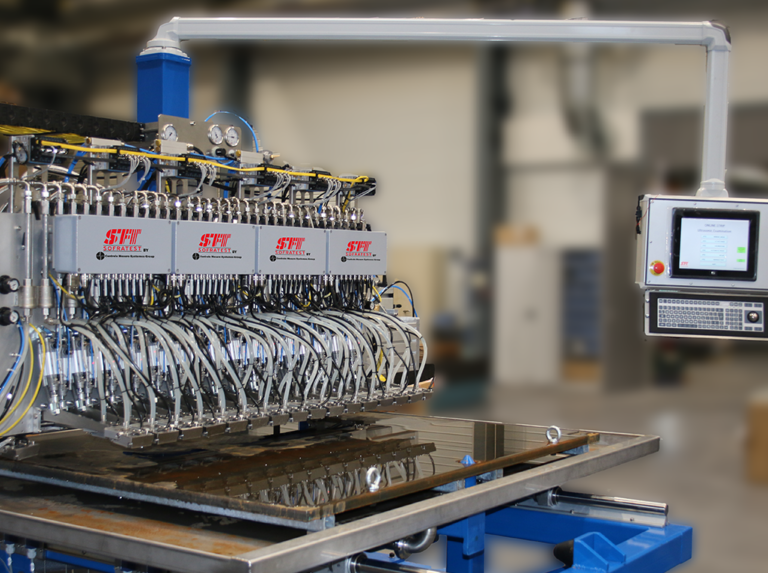

For each strip inspection system, the number of probes is adapted to the width of the strip to be inspected.

For more information, contact us.

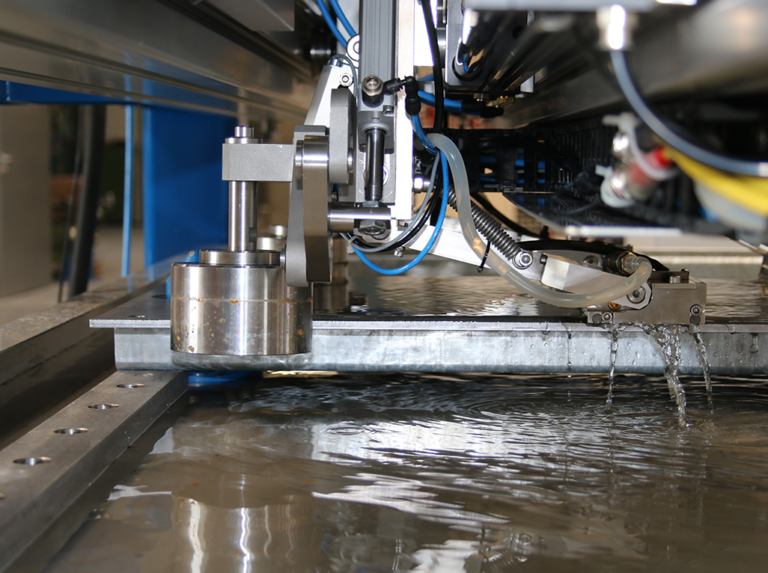

Our Ultrasonic systems facilitate the inspection of strips before forming and welding into a pipe.

In the early stages of the manufacturing process, it will detect both in the body and the edges of the strip:

This inspection system is well-suited for ERW and SAW strips.

Thanks to its robust and reliable mechanics this system can work in harsh environnement

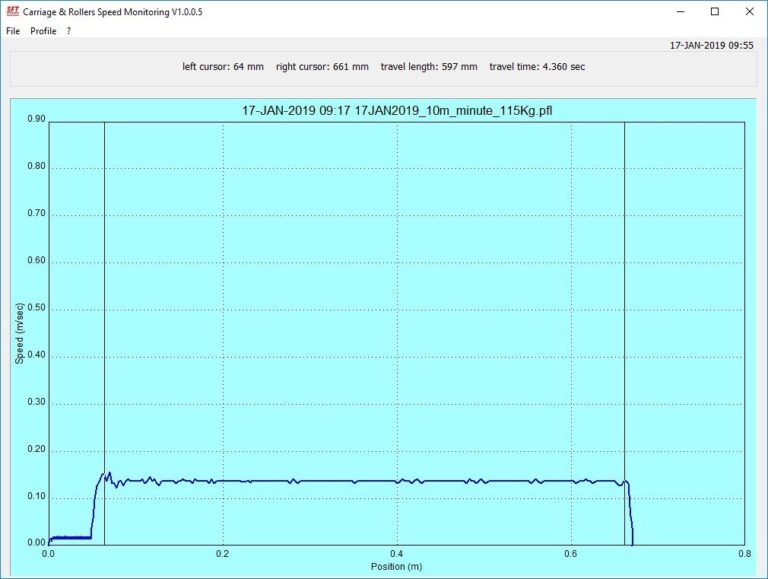

A dynamic calibration, replicating the characteristics of the current inspection, can be conducted. The inspection mechanism glides over a calibration table in an off-line position, consistently performed at intervals during the inspection and at same speed as the one of the mills.

Our equipment adapt to the width and thickness of the strip, enabling the inspection of 100% of the product.

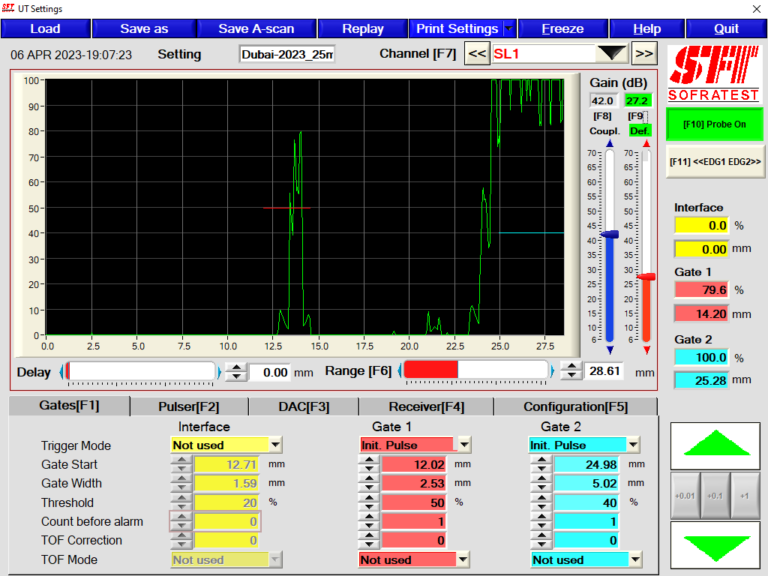

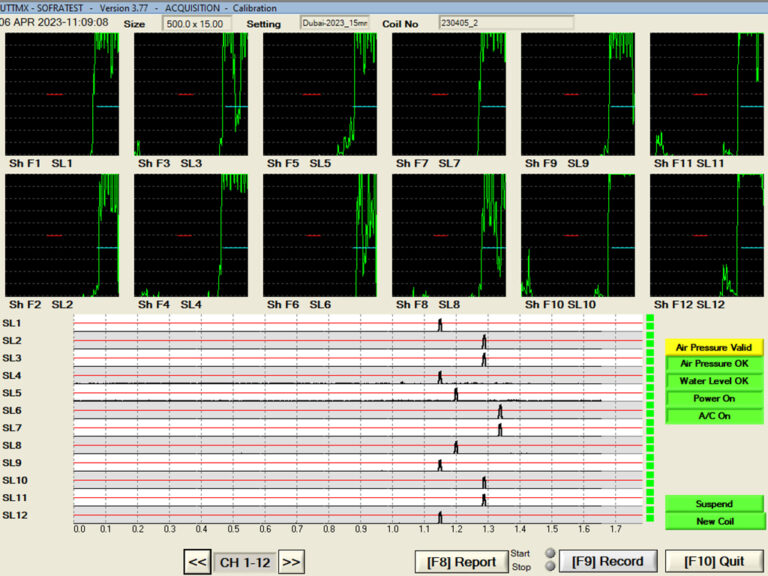

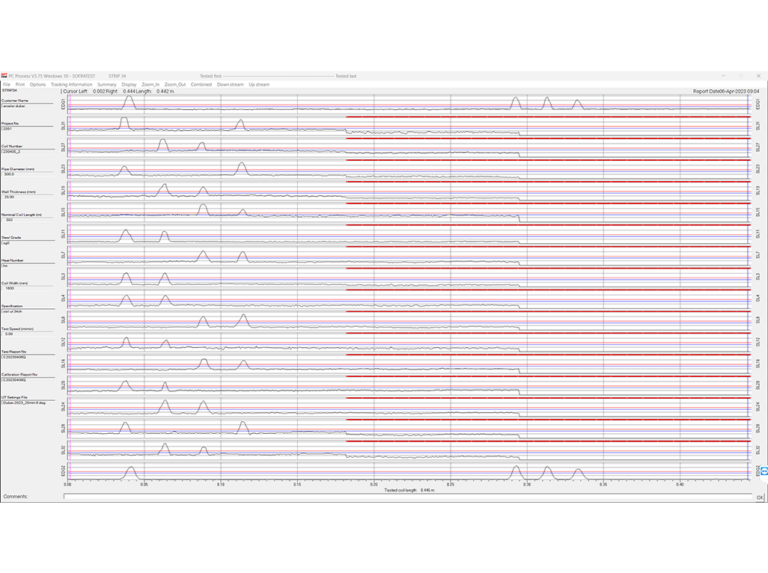

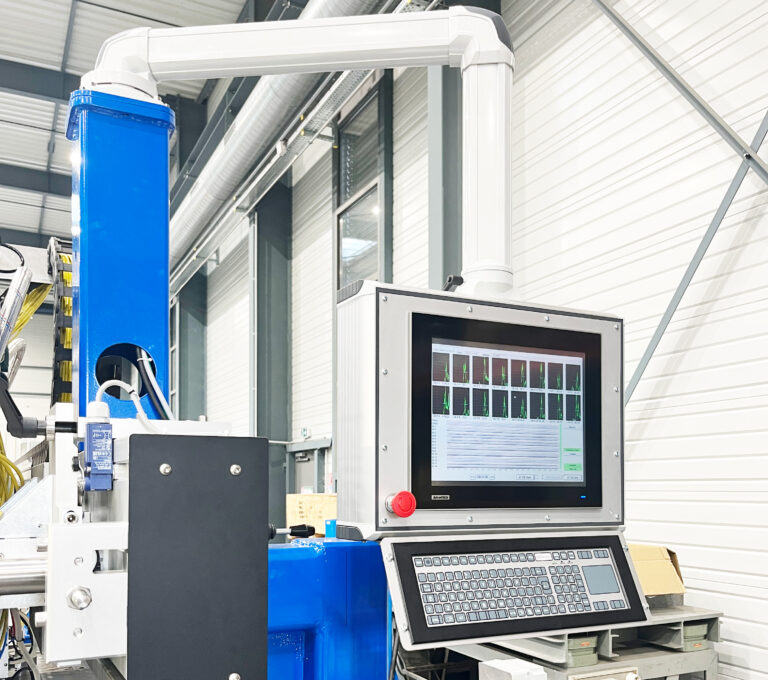

With our robust and user-friendly software, Ultrasonic inspection results are displayed in real-time.

The system screen is remotely accessible, providing a clear, comprehensive view of the ongoing inspection and allowing real-time adjustments (parameters configuration, including gate definition, gain management, marking system settings etc.)

Traceability is guaranteed through our production software, generating comprehensive and customizable inspection reports.

The Speed Profiling Software is specifically designed to chart the speed curve of the calibration table. Upon completing the recording, a profile file is generated and stored, and a dedicated report is created after each calibration.

All our Ultrasonic systems comply with European and international standards, including ASME Section V, ISO 10893-11, 10893-8, 10893-10, API 5L, API 5CT, ASTM E317, and more.

High Inspection Speed

Partial or Complete Strip Inspection

100% Adaptable Systems

Dynamic Calibration

Customizable Inspection Reports

Contact Details

6 rue des Loches

71100 SEVREY | France

Phone : +33.1.34.75.50.00

E-mail : sales@sofratest.com