Home | Electrical Resistance Welding (ERW) | Off-Line Weld Inspection

Home | Electrical Resistance Welding (ERW) | Off-Line Weld Inspection

Thanks to our Ultrasonic expertise, we design and manufacture in-house our UT tailored transducers to suit your detection needs according to your product range.

A wide range of UT trasnducers are available, for more information, contact us.

SOFRATEST provides Ultrasonic inspection solutions for off-line weld inspection of ERW pipes, outside the production line.

Prior to inspection, the ERW pipe is loaded onto the pipe rotator by loading arms. The UT head moves along the main boom to inspect the ERW weld. The pipe remains stationary.

Several defects can be detected:

The inspection head can slide to a standard pipe positioned on a calibration support to perform calibration.

Phased Array sensors can be seamlessly integrated into the SOFRATEST system.

The inspection head can automatically adjust itself in case of deviation from the weld area thanks to the presence of a pilot line tracking system.

A paint marking is available for defects detection and loss of coupling.

SOFRATEST’s designed inspection head perfectly adapts to the different curvatures and diameters of the pipes.

The SOFRATEST inspection head design adapts perfectly to the different curvatures, thickness and diameters of the pipes, enabling a 100% inspection of the product.

To discover our Ultrasonic system for off-line ERW pipe inspection, please visit our Youtube page!

In addition to standard weld inspection, SOFRATEST offers advanced mechanical systems to perform complementary inspections, such as pipe body inspection.

The Ultrasonic (UT) head moves along the main boom, while the pipe is spinning around using pipe rotators, ensuring thorough body inspection. This process enables the detection of lamination defects and coupling losses within the pipe body.

The customization of UT head mechanics and probe characteristics is available to meet specific customer needs and requirements.

Customization of the test heads is also possible to allow inspection of the pipe ends.

Once the inspection is complete, the pipe is unloaded via unloading arms.

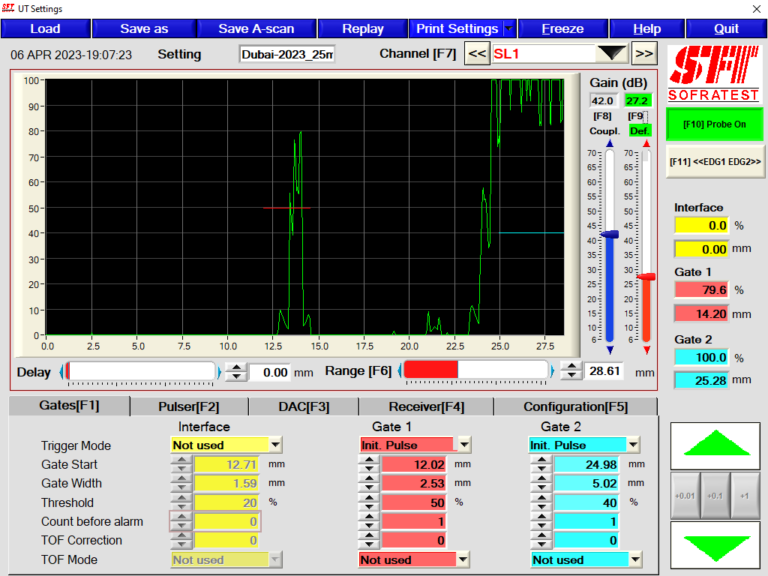

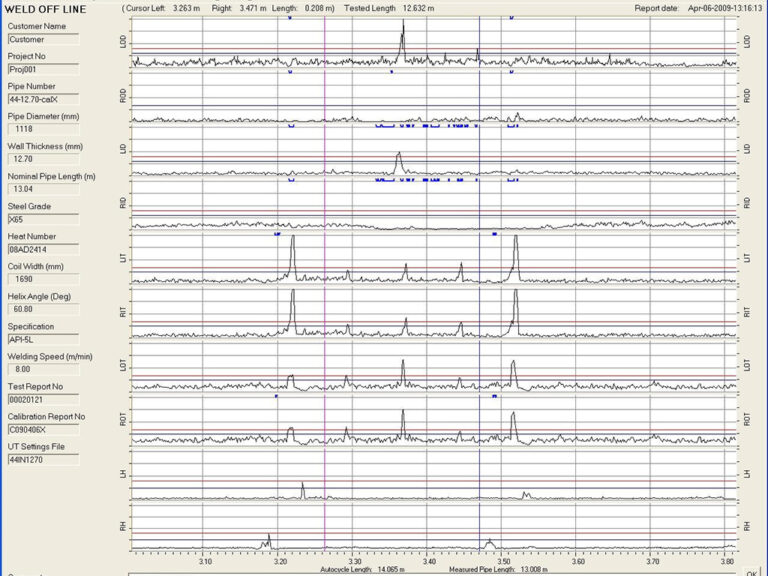

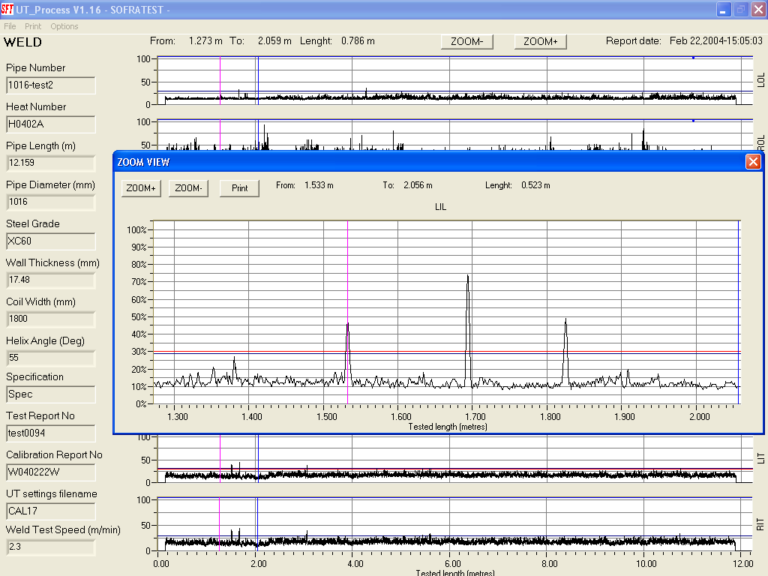

With our robust and user-friendly software, the results of the Ultrasonic inspection are displayed in real-time.

The system screen is accessible remotely, providing a clear, global view of the ongoing inspection and allowing necessary adjustments to be made in real-time, including gate definition, gain management, marking system settings etc.

Traceability is ensured by our production software, creating comprehensive and customizable inspection reports/calibration reports.

All our Ultrasonic systems comply with European and international standards, including ASME Section V, ISO 10893-11, 10893-8, 10893-10, API 5L, API 5CT, ASTM E317, and more.

Equipment Resistant to Harsh Conditions

100% Adaptable Systems

Pipe Position Tracking System

Fast Inspection Speed

Dynamic Calibration

Customized Inspection Report

Contact Details

6 rue des Loches

71100 SEVREY | France

Phone : +33.1.34.75.50.00

E-mail : sales@sofratest.com